Ubushushu obuphezulu beThermal Insulation Ceramic Fiber Gasket

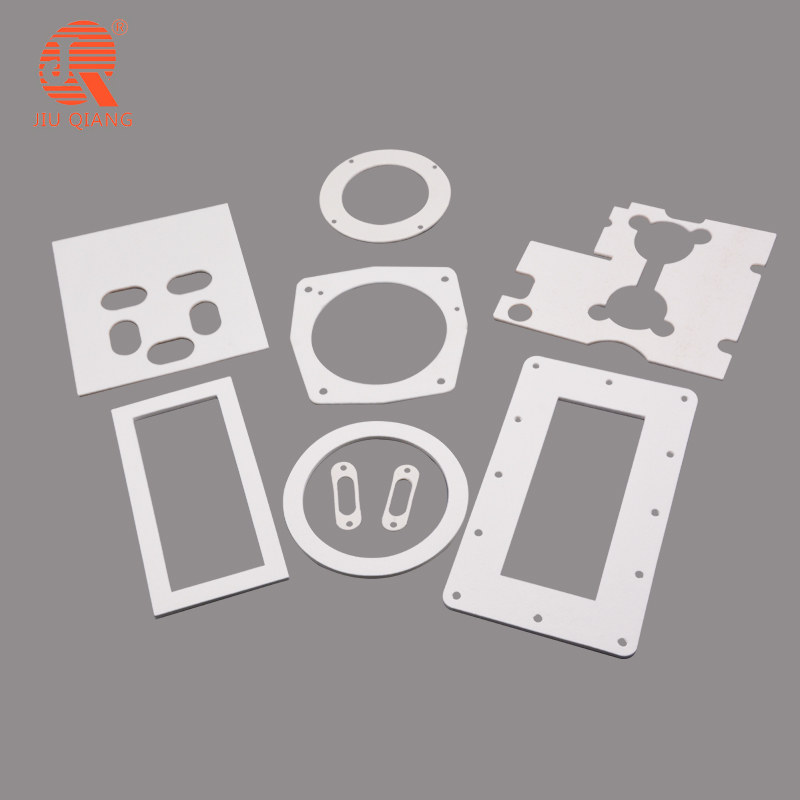

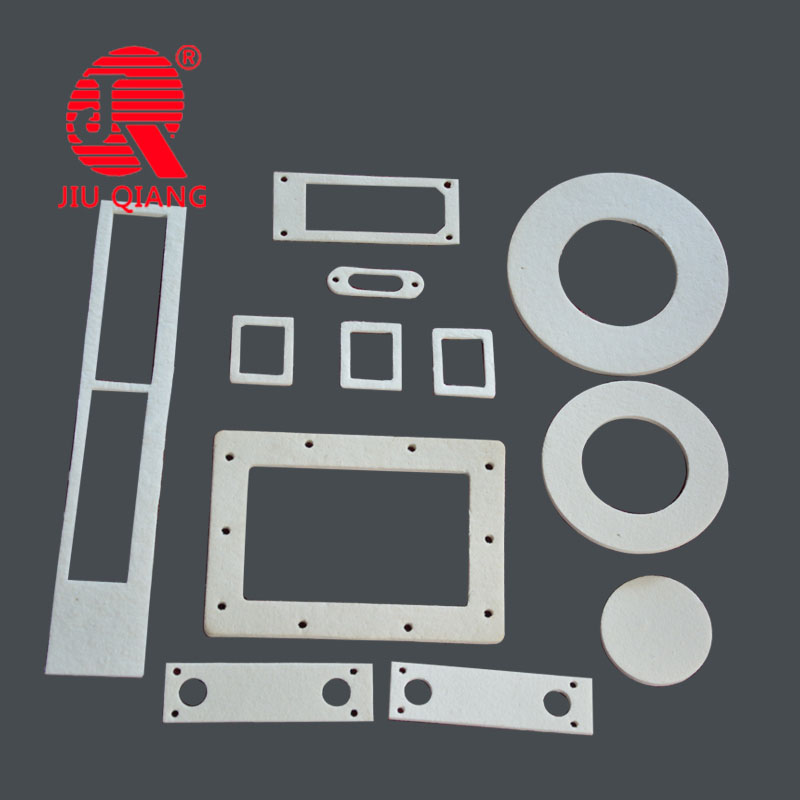

Iimilo ezahlukeneyo zinokulungiswa ngokweemfuno zabathengi.

● Thepha i-Hole cones.

● Imikhono yokuKhuphuka.

● Imikhono yokuKhuphuka.

● Ilayile yophahla.

● Ukugalela iindebe.

inzuzo

Inzuzo ye-ceramic fiber shape

1. I-conductivity ephantsi ye-thermal kunye nokugcinwa kobushushu obuphantsi.

2. Amandla aphezulu wokucinezela.

3. Kulula ukuyifaka.

4. Uzinzo olugqwesileyo lobushushu kunye nokumelana nokutshatyalaliswa kwe-thermal.

5. Umphezulu ogudileyo.

Ukungcola okuphantsi, kunye ne-avareji yobuninzi bobuninzi kunye nobukhulu.

Amandla omatshini agqwesileyo kunye namandla okwakhiwa.

isicelo

Ukusetyenziswa kwemilo yefiber ceramic

1. I-Industrial furnace wall lining kunye nezitena-up insulating layer.

2. Izinto zokufudumeza ubushushu bobushushu obuphezulu kunye nezixhobo zobushushu obuphezulu.

3. Ukushisa ubushushu, ukungabikho komlilo, ukugquma isandi kunye nezixhobo zombane zombane kwi-aerospace kunye neshishini lokwakha iinqanawa.

4. Iziko lobushushu obuphezulu, i-onti yemoto, i-baffles yamacango kunye nezahluli ze-kiln.

Ishiti yedatha

| IBanga | Umgangatho | I-Aluminiyam ephezulu | Zirconium | ||

| UHlelo loHlelo(℃) | 1260℃ | 1300 | 1430 | ||

| Ubushushu bokusebenza (℃) | 1150℃ | 1260 | 1400 | ||

| Ubuninzi (kg/m3) | 300-450KG/M3 | ||||

| I-Thermal conductivity nge-meat temp.(w/mk)(Uxinzelelo 285kg/m3) | 0.085 (400℃) 0.132 (800℃) 0.180 (1000℃) | ||||

| Amandla oxinzelelo (Mpa) | 0.5 | ||||

| Ukuqina | Kuhle kunzima | ||||

| Nxiba ukuxhathisa | Abanye | ||||

| IkhemikhaliUkuqamba | AL2O3 | 42-43 | 52-55 | 32-33 | |

| AL2O3+SIO2 | 97 | 99 | -- | ||

| ZrO2 | -- | -- | 15-17 | ||

| Fe2O3 | <1.0 | 0.2 | 0.2 | ||

| Na2O+K2O | ≤0.5 | 0.2 | 0.2 | ||

| Amagqabantshintshi: le datha ingentla yeyoreferensi.UMax.ixesha.kuxhomekeke kwiimeko zokusebenza. | |||||

Iipakethi ze-ceramic fiber shape

1. Ikhathoni kunye nengxowa yeplastiki ngaphakathi.

2. I-Pallet, yokuqwalaselwa komthwalo kunye nokukhulula.